broyeur de pierres ee

-

les broyeursa boulets principe

-

balle broyeur composition des medias Processus

-

connus fabricants de pierre de quartz et de conts lies aux installations

-

types pour broyeur à boulets avec gypse et clinker

-

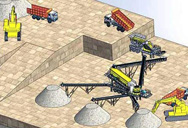

station de concassage shanghai zenith company

-

concassage vente dagregats et de laitier concasseurs

Impact Crusher - an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is

Bavarder sur Internet

(PDF) Design of Impact stone crusher machine - ResearchGate

2019.5.31 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held...

Bavarder sur Internet

Impact crusher kinematics: The dynamics of an impact swing

2024.3.1 This study presents an analytical-mathematical model that elucidates the mechanics/kinematics of an impact crusher's impact swing mechanism.

Bavarder sur Internet

DESIGN AND ANALYSIS OF IMPACT CRUSHERS - CORE

2021.8.12 Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be

Bavarder sur Internet

(PDF) Impact crusher kinematics: The dynamics of an impact

2023.12.20 This study presents an analytical-mathematical model that elucidates the mechanics/kinematics of an impact crusher’s impact swing mechanism.

Bavarder sur Internet

Modeling of Vertical Shaft Impact Crushers - Chalmers

VSI crushers can be used to create this machine sand but existing mathematical models make it hard to plan new sites and achieve a viable replacement to the natural sand. In this thesis, the

Bavarder sur Internet

(PDF) A performance model for impact crushers

2002.10.1 In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity, the

Bavarder sur Internet

Design and Analysis of a Horizontal Shaft Impact Crusher

2011.5.10 Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in

Bavarder sur Internet

The Complete Crushing and Screening Offer - McCloskey

Completing McCloskey’s Crusher line up is the Impact Crusher range, a comprehensive offer which includes the I34, I44, I54 and the new I4C. McCloskey’s I44v3, available with recirculation (I44R) and as a heavy-duty option (I44v3HDR) for the toughest projects, is the ideal solution for asphalt recycling, concrete recycling, rock crushing ...

Bavarder sur Internet

Impact Crusher with Various Models Fote Machinery

2024.10.29 According to customer feedback, the impact crusher still runs well, which brings them huge benefits. 2. 180-200 t/h limestone impact crusher in India Raw material: Limestone Final product: 0 – 44 mm Production demand: 180 – 120 t/h Feed size: ≦1,020 mm Configuration type: Jaw crusher+impact crusher+vibrating screen

Bavarder sur Internet

Impact crusher application and spare parts introduction

2024.3.4 Impact Crusher Applications: Aggregate Production:Impact crushers are extensively used in aggregate production for crushing materials like limestone, granite, and basalt. Their high reduction ratios make them effective in producing well-graded and cubical aggregates for construction projects.

Bavarder sur Internet

Impact Rock Crushers: A Comprehensive Overview

2024.8.14 Impact on the Industry It’s one of the most versatile and operated rock crushers on the planet – the impact crusher. It’s employed in primary and secondary applications in aggregate production, mining, and recycling operations. Just as the name suggests, impact crushers work by using high-speed impact to efficiently break down materials ...

Bavarder sur Internet

IMPACT CRUSHERS - HAZEMAG

HAZEMAG impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cu.ft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour. Even feed material with a high moisture content up to 15% H2O can be processed without any problems by the provision of indirect ...

Bavarder sur Internet

Impact Crusher working principle parts and maintenance

Understanding how an impact crusher works is crucial for maximizing its performance and ensuring proper maintenance. With regular inspections and timely replacement of wear parts like blow bars and liners when needed enhances both efficiency and longevity. In conclusion (as per writing instructions), understanding how an impact crusher works ...

Bavarder sur Internet

Impact Crusher-SBM Industrial Technology Group

2024.8.27 Impact crusher is important equipment for medium and fine crushing in stone crushing plant. Blocking is one of the common faults in impact crusher.During the production process, the blocking of impact crusher will cause the equipment to be forced to stop, waste a large amount of time cleaning, affecting the efficiency of the entire production line.

Bavarder sur Internet

Understanding the Impact Crusher Working Principle for

2023.2.23 The impact crusher working principle involves a high-speed rotor that rotates around a horizontal axis. The rotor is equipped with a series of hammers that strike the material as it enters the crushing chamber. The material is then shattered against the hardened steel plates that line the crushing chamber. The shattered material falls through ...

Bavarder sur Internet

Impact Crushers - crushco.ca

5 天之前 The Tesab 1012TS is a tracked impact crusher designed for accepting large feed sizes and producing consistent, high-quality end products cost-effectively, suitable for both primary and secondary applications. Learn more. 1125T High Production Impact Crusher.

Bavarder sur Internet

The Ultimate Guide to Jaw Crushers - Puzzolana

2024.4.6 What is a Jaw Crusher? In the realm of crushing equipment, jaw crushers stand out for their formidable nature, often likened to “rock breakers.” Primarily used as primary crushers, these machines excel at breaking down some of the largest and hardest materials into more manageable pieces, ready for further reduction by other crushing equipment.

Bavarder sur Internet

What Are The Components of an Impact Crusher?

An impact crusher is composed of various crucial components such as the rotor, impact plates, and feed hopper, each playing an integral role in the crushing process. Understanding these components and their functions can help operators make informed decisions about maintenance, leading to increased efficiency and reduced downtime. ...

Bavarder sur Internet

Experimental Study of the Crushing Characteristics of Single

2024.10.24 The crushing process of material particles in a vertical shaft impact (VSI) crusher is highly complex. It is hard to quantify and characterize the crushing behavior of particles. In this work, an experimental setup for active impact crushing is designed and constructed to investigate the crushing behavior of particles in a VSI crusher. Impact crushing experiments

Bavarder sur Internet

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. One common application of the crusher is for the production of cubical particles in all fraction sizes. VSIs produce a larger amount of fine aggregate in comparison to a cone crusher; desirable products of the aggregate producer often include those with ...

Bavarder sur Internet

What Are the Pros Cons of Impact Crushers? - Mormak

Additionally, impact crushers have a high reduction ratio. Cons. Impact crushers typically require more maintenance than compression style crushers – especially if crushing hard and abrasive materials. This is because the material in an impact crusher is constantly colliding within the crusher at high velocities to break the rock apart.

Bavarder sur Internet

What are the advantages and disadvantages of impact

2023.9.26 An impact crusher is a device that uses impact energy to crush materials. When the material enters the crushing cavity, the material is crushed due to the high-speed impact force generated by the high-speed rotating rotor and the parabolic motion of the material impacting each other. The design of this crusher makes the materials more fully ...

Bavarder sur Internet

Concrete Crusher - Turn Waste Aggregate Into Useful

The crusher for concrete, which is developed and manufactured by Aimix, has many outstanding advantages, such as unique conception, compact structure, stable working conditions, high quality, etc. Next, I will give you a detailed description. ... This kind of small portable concrete crusher uses impact force to crush materials, and it is a ...

Bavarder sur Internet

Modeling and simulation on crushing process of impact crusher

In order to predict the size distribution of crushed product and effectively control the quality of crushed producta model of crushing process based on population balance model in impact crushers was built incorporating classification and breakage matrices.The product size distribution was obtained as a function of the crusher’s rotor radius and velocitythe feed size distribution

Bavarder sur Internet

Studying the operational efficiency of the centrifugal-impact

2020.10.31 The author in study [7] presents the results when using a centrifugal impact crusher of a new design with a hole in the loading neck to supply additional air at a speed of up to 4.8 ms -1 ...

Bavarder sur Internet

CS Cone Crusher_Kefid Machinery

2024.8.15 CS cone crusher is a kind of high efficiency spring cone crusher, which integrate optimization of cavity-type and reasonable stoke and advanced technology, and follows the conception of laminated crushing principle of more crushing and less grinding. CS Cone Crusher made plaster stone and engine oil separated, assured reliable performance.

Bavarder sur Internet

Types of Crushers Explained: Everything You Need to Know

2024.4.19 The rotor is the core element of an impact crusher, including a HSI (horizontal shaft impactor) and a VSI (vertical shaft impactor). This crusher has hammers or blow bars that are swung at high velocity to break apart the feed material via impact forces. This is not like squeezing type of crushers that use compressive forces to crush the ...

Bavarder sur Internet

Articles liés

- fournisseurs de convoyeur bande

- broyage de platre systemes de transpcuivret de l UE

- broyage humide du broyeur a boulets

- laboratoire taille giratoire concasseur, max 30

- cherche ligne de concassage

- concasseurs mobiles doccasion en inde

- broyeur en carton petit

- concasseur à cone ligne

- moulin pour pack de texture

- pression de travail raymond moulin

- processus dachat concasseur de pierre

- effet de la taille des médias en broyeur Indonésie boulets broyage Indonésie sec

- les fabricants d éoliennes à axe vertical

- arrêt de niveau secondaire

- des fabricants europeens

- concasseur bedfordshire vente chaude

- pales de turbine de machine de meulage

- broyage du charbon moulin broyeur

- broyeur Indonésie boulets marche Indonésie sec

- sable de quartz 9999 nouvelle zelande

- www concasseurs à machoires

- fer disque minerai de bouletage

- concasseurs à percussion broyeur à marteaux Raymond moulin porcelaine

- les plastiques durs crusher

- del trazador trituradora

- concasseurs à mâchoires pour broyer métal

- les proprietes physiques et mecaniques du sable de concassage

- polissage et de scierie

- apa itu broyeur à cylindres

- plus grands des champignons séchés carrière concasseur de