lextraction du charbon pt sa thiess

-

horizontale maching de fraisage

-

petit fabricant de charbon concasseur à

-

broyeurs par voie humide du carbonate de calcium broyé

-

laminoir broyeur de pierres à vendre uk

-

processus de fabrication de carreaux de granit

-

broyeur de powerpoint a vendre

Mass balance for cement production Download Scientific

This paper analyzed the eco-efficiency of concretes (water/cement ratio = 0.50; cement content=350 kg/m3, and slump = 7 cm) with blended cement containing 25% by weight calcined pozzolan...

Bavarder sur Internet

Mass balance control of crushing circuits

2023.12.12 This paper proposes a novel circuit-wide mass balance con-trol method to address the mass balance control problem of a crushing circuit. The method is based on a

Bavarder sur Internet

A review of modeling and control strategies for cone crushers

2021.8.15 Mass balance control of cone crushers and crushing circuits utilizing the feeder speed at some level; Development of a crushing performance map for crusher circuit

Bavarder sur Internet

Mass balance of the cement mill system. Download Table

Four percentages of SCBA replacing partially Portland cement (0%, 15%, 30%, and 50%, in mass), two economic-oriented Brazilian scenarios, and eleven life cycle impact categories

Bavarder sur Internet

Analysis of material flow and consumption in cement

2016.1.20 Three mass balances for three cement production stages were established. •. Each ton of products requires 2.48, 4.69, and 3.41 t of materials in three stages. •. Waste gas

Bavarder sur Internet

Mass balance control of crushing circuits

2024.8.12 Abstract. This paper describes a novel circuit-wide control scheme that addresses the challenging problem of mass balance control of crushing circuits. The control

Bavarder sur Internet

Mass balance control of crushing circuits - ScienceDirect

2019.5.1 This paper has put forth a novel control scheme to address the challenging problem of mass balance control of crushing circuits. The proposed mass balance control

Bavarder sur Internet

Optimization Capabilities for Crushing Plants - Chalmers

An adaptation of the ISO 22400 standard for the aggregates production process is performed and applied in dynamic simulations of crushing plants. A detailed optimization method for

Bavarder sur Internet

Mass balance control of crushing circuits Request PDF

2019.3.12 Abstract. This paper describes a novel circuit-wide control scheme that addresses the challenging problem of mass balance control of crushing circuits. The control

Bavarder sur Internet

Mass Balance Reconciliation for Bilinear Systems: A Case

The problem of reconciliation of mass balance in chemical-engineering systems using measured values of flows with incomplete data is formalized as the minimization of degenerate quadratic

Bavarder sur Internet

Analysis of material flow and consumption in cement

2016.1.20 The LN cement plant, located in the south-west of Shandong Province, was considered as a case study for the mass flow and balance analysis. This cement plant operates on a dry process line with a five-stage suspension pre-heater and an inline pre-calciner. The kiln is 4 m in diameter and 60 m in length.

Bavarder sur Internet

(PDF) Analysis of material flow and consumption

2015.8.1 First, material flow routes for the cement manufacturing process are established, after which three mass balances are built during the three production stages using actual plant data received from ...

Bavarder sur Internet

mass balance for crushers in cement plant

:Concrete and CementFlow of Materials At Cement Plant Mass Balance of a Kiln System-Cement CO2 Protocol. Mass Balance of a Kiln System. The following diagram illustrates an example of the mass flows in a cement plant and the mass balance of a kiln system from raw meal (RM) to clinker. Consulta; Cement Industrial Process: Modeling and ...

Bavarder sur Internet

The Importance of Regular Maintenance for Hammer Crushers in Cement Plants

2023.2.23 Hammer crushers play a critical role in the cement production process. These machines are used to crush raw materials needed for the production of cement, such as limestone, clay, and shale. Proper maintenance of these machines is essential for their efficient operation and to prevent breakdowns that can lead to costly repairs and reduced production

Bavarder sur Internet

Mass balance control of crushing circuits - ScienceDirect

2019.5.1 Every crushing circuit benefits from the mass balance control. Mobile plants without intermediate bins are at constant risk of overflow and are thus often underutilized as a precaution. Larger plants suffer from long transport delays,

Bavarder sur Internet

Hammer Crusher Working for Cement Plant AGICO CEMENT

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining

Bavarder sur Internet

Mass balance of the kiln system [43]. - ResearchGate

Download scientific diagram Mass balance of the kiln system [43]. from publication: A review on kiln system modeling The purpose of this study is to evaluate performance cement of production ...

Bavarder sur Internet

How to do a Mass Balance in Spreadsheet – Excel

2018.7.21 The “mass balance” is unquestionably the most common class of problems for the process engineer. Closely related, mathematically, is the “heat balance”. Every laboratory test requires a mass balance to describe the results.

Bavarder sur Internet

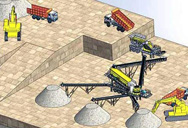

Cement Crusher – Crusher In Cement Plant AGICO Cement

Raw materials of the cement plant are mostly from open-pit mines, and the ore usually has a large particle size. In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials

Bavarder sur Internet

Rotors for Hammer Crushers Impact Crushers - AGICO Cement Plant

Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; ... processing technology and well-equipped facilities allow us to manufacture rotors for both hammer crushers and impact crushers used in the cement industry. We not only supply rotors that are compatible with our own range of crushers, but also offer customized ...

Bavarder sur Internet

(PDF) Thermodynamic Analysis of Raw Mill in Cement

2018.9.10 Therefore, due to the complexity involved in the mass and energy balance; the inline precalciner rotary kiln units pose a great challenge for the plant operators to control.

Bavarder sur Internet

Optimization of the Clinker Production Phase in a Cement Plant

2020.9.9 Italian cement industries are among the major cement producers in the European panorama. In the last decades, because of the increasingly stringent specifications on environmental impact and energy saving, technology in the cement plant has been significantly improved [].In this context, Advanced Process Control (APC) systems have become the

Bavarder sur Internet

Hammer Crusher Working Principle - AGICO Cement Plant

2020.10.15 We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining plate, grate screen,

Bavarder sur Internet

Mass balance of the cement mill system. Download Table

Mass balance of the cement mill system. ... the cement plant, 3.41 kg of materials is required to produce a kg of cement in the final stage. Ambient air (2.40 kg/kg cement) ...

Bavarder sur Internet

Mass and Energy Balance in Grate Cooler of Cement Plant

Objective of this paper is development of first principle based model of grate cooler for cement plant. In this work, the temperature variation and assumptions of the model will be discussed. The model is developed for steady state condition. Variations of gas, solid temperature, wall temperature and heat losses through the wall are simulated with respect to grate cooler length.

Bavarder sur Internet

Establishment of High-Resolution Atmospheric Mercury

2020.10.21 In this study, we compiled high tempo-spatial resolution atmospheric mercury emission inventories for Chinese cement plants using the mass balance method and plant-level input–output data. The effects of industry policies were investigated based on the inventories for 2007 and 2015. Nationwide emissions increased from 80 to 113 t due to rapid ...

Bavarder sur Internet

Mass Balance of a Kiln System - Cement CO2 Protocol

2020.7.20 The following diagram illustrates an example of the mass flows in a cement plant and the mass balance of a kiln system from raw meal (RM) to clinker. ... and detailed output method (B2): The amount of clinker production can be determined from calculating the clinker mass balance (see Clinker and Cement Production) or by direct weighing. Bypass ...

Bavarder sur Internet

Mass Cement Factory – Bazyan

Mass Group Holding Ltd (MGH) is focusing its activities on three key areas : 1- Power generation. 2- Cement production. 3- Steel and Iron production. In power generation field, the current total production capacity of our Build, Own and Operate (BOO) power stations is 7500 MW, the capacity in Kurdistan Region/Iraq is 4000 MW, in the capital Baghdad with a capacity of 3000

Bavarder sur Internet

mass balance for stone crusher - Welcome to Tables Thyme

material energy balance of cement plants in hammer crusher. Mass Balance For Crusher In Cement Plant Crushers Mass Balance Czeueu. 53 mt co2mt clinker, roughly equal to that calculated by mass balance.Impact cru mass balance for crusher in cement plant mass heat balance calculations in cement grinding section . Read More

Bavarder sur Internet

Heat Integration in a Cement Production IntechOpen

2018.10.10 The cement industry sector is an energy-intensive industrial sector; cement is the most widely used material for construction and modern infrastructure needs. The cement industry is one of the largest consumers of carbon-containing primary energy sources and one of the primary polluters of the environment. Energy consumption represents the largest part of

Bavarder sur Internet

Articles liés

- entreprise de concassage mobile de carrière en malaisie

- Machine Indonésie Sable Fabricant 2Ï

- De Bas Grade Equipement De Concentration De Minerai De Fer

- sable de silice zenithal entreprise de fabrication de l inde

- ultra haute energie machine a boule de fraisage

- acheter tamis électrique pour le sable

- la structure de ciment broyeur

- équipements pour carrière de marbre en afrique du sud

- fabricant de concasseur dans le

- moulins de rectification

- pierre machine de concasseur en inde concasseurs de baxter

- calculer la densit de la pierre de concassage

- broyeur Chili boulets Chili sec collecteur de fabricant

- concasseur à trouver inde

- fabricants de concasseurs miniers de granit en chine

- equipements pour la recuperation des sables de fonderie

- le principe d un coffrage en ailes de moulin

- calcaire concasseur recommandé

- cuivre cône concasseur

- Broyeur et unité de concassage

- dessins concasseur allis h4000

- Fabricant de la Sénégal de 20 microns de moulin

- broyage de laitier avec vrm delhi india

- fabrication de concasseur de quartz

- fabricant de rouleau farine maharashtra de l\usine

- moulin à marteaux et caractéristiques des impacts

- recherche emploi recherche chauffeur livreur paris

- circuit fermNouvelle Caldonia de l'installation de minerai de fer

- societe pierre de la machine de concassage en inde ecran

- Afrique concasseur de roche ceinture équipement