les technique de l'usine balle de fin de nez

-

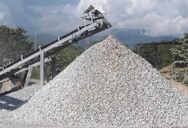

moulin concasseur usine de concasseur mobile a dubai

-

principe de fonctionnement du concasseur Indonésie mâchoires hydraulique

-

moulin magique manuel meuleuse moulin

-

le processus dl'un concasseur primaire

-

broyeur a marteaux Drotsky a vendre

-

concasseur etalonnage que le convoyeur

Quartz Ball Mill Quartz Sand Ball Mill for Quartz Mineral

Quartz ball mill (quartz sand ball mill) is a specialized quartz grinding equipment developed on the basis of traditional ball mill combining the characteristics of quartz ore. The quartz ball mill

Bavarder sur Internet

球磨分级生产线 – 埃尔派粉碎机-超细石英粉硅微粉处理专家

2024.10.30 球磨机+分级机系统主要特点. 球磨机采用特殊设计和适当配比的研磨介质,达到理想的研磨细度。. 篦板式出料,出料通畅,筒体不需要冷却;. 对球磨机的进料采取连续控

Bavarder sur Internet

Quartz Ball Mill- China Ball Mill - alpamill

2023.6.14 Quartz ball mill is a specialized equipment developed on the basis of traditional ball mill combined with the characteristics of the mine. During the grinding process of quartz,

Bavarder sur Internet

Quartz Sand Wet Grinding Ball Mill - JXSC Machine

2019.12.5 Quartz ball mill is a special type of ball mill machine series, can grind other ore similar to the physical and chemical properties of quartz, such as feldspar, sandstone,

Bavarder sur Internet

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to

Bavarder sur Internet

Quartz sand ball mill - Zoneding Machine

2023.7.31 The quartz sand ball mill is designed to grind quartz sand into particles with a controlled particle size of up to 325 mesh (0.045mm). The feed size of the crushed quartz

Bavarder sur Internet

Ball Mill for Quartz Grinding Manufacturers in China

2023.10.10 Quartz ball mills have low energy consumption compared to other types of mills used in mineral processing. This means lower operating costs and reduced

Bavarder sur Internet

China Quartz Ball Mill, Quartz Ball Mill Wholesale,

China Quartz Ball Mill wholesale - Select 2024 high quality Quartz Ball Mill products in best price from certified Chinese Mill manufacturers, Mining Machinery suppliers, wholesalers and

Bavarder sur Internet

quartz ball mill user ‘s manual - planetary ball mill

2024.7.29 Section 1: Introduction to Quartz Ball Mills. Brief overview of ball milling process. Applications of quartz ball mills in various industries. Key components and their functions.

Bavarder sur Internet

Quartz powder ball mill production line in an Anhui mineral

2024.11.5 After conducting a series of tests and analyses, Epic designed two sets of airflow classifier production lines according to the requirements and successfully delivered

Bavarder sur Internet

Quartz sand ball mill - Zoneding Machine

2023.7.31 Quartz sand ball mill Quartz sand is an important industrial mineral used in various industries such as glass, casting, and ceramics. To meet specific purity requirements, quartz sand is often further processed through crushing and grinding. For fine particle size grinding, a quartz sand ball mill is commonly used. The quartz sand ball mill is

Bavarder sur Internet

The Influence of the Grinding Media Diameter on Grinding

2024.6.14 This article presents experimental studies of the grinding process of a model material (quartz sand) in a laboratory vibratory mill. Five sets of grinding media with different diameters were used in the research, and grinding was conducted for various durations. ... In a ball mill, the grinding media receive energy from the rotating chamber ...

Bavarder sur Internet

Facile, fast, and green preparation of high-purity and quality

2023.1.12 In this study, silica nanoparticles (SiO2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, cost-effective, and green approach. The sol–gel method was also used to produce these NPs as a comparative method. The SiO2 NPs produced by both methods were characterized using high-resolution transmission electron microscopy

Bavarder sur Internet

Evaluation of particle size reduction and agglomeration in

2020.5.15 Dry grinding experiments were carried out for up to 1920 min in a planetary ball mill operating at 300 rpm using quartz particles from milky and clear blocks with similar hardness and fracture toughness. Particle size distribution, specific area and the morphology of finely ground powders were characterized by laser scattering, nitrogen ...

Bavarder sur Internet

Grinding Media in Ball Mills for Mineral Processing

2023.11.24 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. ... Quartz is one of the most pervasive abrasive materials in mineral processing. The chemical composition, microstructure and hardness of grinding media influence the extent of abrasion wear during milling.

Bavarder sur Internet

quartz ball mill user ‘s manual - planetary ball mill

2024.7.29 Section 1: Introduction to Quartz Ball Mills Brief overview of ball milling process Applications of quartz ball mills in various industries Key components and their functions Safety precautions Section 2: Installation and Setup Unpacking and inspection Base preparation and leveling Electrical connections Mill assembly (if applicable) Alignment and balancing Section 3:

Bavarder sur Internet

Evaluation of particle size reduction and agglomeration in

2020.4.1 This study investigates particle size reduction and interparticle agglomeration in clear and milky quartz ground in a planetary ball mill for up to 32 h. Particle size distribution and specific ...

Bavarder sur Internet

Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer - Tongli

Ball mill girth gear. Rotary kiln thrust roller. Ball mill trunnion. Rotary kiln pinion. Ball mill head. Rotary kiln roller shaft. Ball mill bearing bush. Rotary kiln bearing housing. Ball mill bearing housing ManufacturerFactory. Rotary kiln spring plate ManufacturerFactory. Ball mill transmission connection ManufacturerFactory

Bavarder sur Internet

A Review of the Grinding Media in Ball Mills for Mineral

2023.10.27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

Bavarder sur Internet

Ball Mills - 911Metallurgist

2017.2.13 Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs. They may be used for pulverizing and either wet or dry grinding systems. Mills are available in both light-duty and heavy-duty construction to meet your specific requirements.

Bavarder sur Internet

Evaluation of particle size reduction and agglomeration in

2020.5.15 Dry grinding experiments were carried out for up to 1920 min in a planetary ball mill operating at 300 rpm using quartz particles from milky and clear blocks with similar hardness and fracture toughness. Particle size distribution, specific area and the morphology of finely ground powders were characterized by laser scattering, nitrogen ...

Bavarder sur Internet

Quartz Sand Wet Grinding Ball Mill - JXSC Machine

2019.12.5 Quartz ball mill is a special type of ball mill machine series, it is named after the material quartz, but not limited to grinding quartz. It can also grind other ore similar to the physical and chemical properties of quartz, such as feldspar, sandstone, dolomite, shale.

Bavarder sur Internet

quartz grinding ball mill manufacturar - LinkedIn

2023.11.22 Precision Grinding Excellence: Quartz Grinding Ball Mill by SBM 🌐. Project Background: In the thriving landscape, where mineral processing plays a pivotal role in various industries, we are ...

Bavarder sur Internet

How to Grind Quartz Crystals: The Ultimate Guide - 33rd

2023.10.19 3. Ball Mill. Load crushed quartz into the ball mill with steel balls. Add water to just cover the raw material to minimize dust. As quartz and steel balls tumble within the rotating mill, the steel balls pulverize the quartz into a fine powder. Grind quartz down to the optimal size such as 200 mesh or less for desired uses.

Bavarder sur Internet

Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale

The mini ball mill is a type of small-scale ball mill, suitable for trial production and small batch production. AGICO offers high-efficiency mini ball mills at a competitive price. ... chemical industry, etc. It is a necessary device for processing quartz stone, cement clinker, nano materials, and high-tech materials. Free Services We Offer ...

Bavarder sur Internet

The Advantages of Using Quartz Ball Mill in ... - ball mills

The use of quartz ball mills in mineral processing applications has gained popularity due to their high efficiency and cost-effectiveness. Understanding Quartz Ball Mills. A quartz ball mill is a type of ball mill that uses quartz as the grinding media. The grinding media is the balls, which may be made of steel, stainless steel, ceramic, or ...

Bavarder sur Internet

Enhancing Productivity with Quartz Grinding Machine

2023.11.28 Quartz ball mill is a type of grinding equipment used to grind quartz crystals and other similar materials into fine powder. It consists of a horizontal cylinder with a rotating drum, which is partially filled with grinding media such as ceramic balls or steel balls. As the drum rotates, the grinding media cascade and impact the quartz ...

Bavarder sur Internet

Mechanochemical destruction of mirex co-ground with iron and quartz

2013.2.1 Quartz, a low cost and largely available material, has been found to prompt the degradation efficiency of chlorinated POPs like PCBs (Zhang et al., 2001). (2) ... And in ball mill machine designing and manufacturing, rotation speed is

Bavarder sur Internet

Ball Mill Design/Power Calculation - 911Metallurgist

2015.6.19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of

Bavarder sur Internet

Ball Mill and Air Classifier Production Line - ALPA Powder

2024.10.31 The ball mill adopts special design and suitable proportion of grinding medium to achieve ideal grinding fineness; The slab-type grinding tail discharges, the discharging is smooth, and the cylinder does not need to be cooled; ... Quartz powder ball mill and air classifier production line in a mineral factory in Shandong.

Bavarder sur Internet

Articles liés

- concasseur de pierre prix d usine inde en inde

- les fournisseurs de la machine de sablage

- cout de l usine de materiaux de construction

- broyeur de déchets de tyrannosaurus chaîne de pièces en

- taille d'alimentation au concasseur giratoire

- fabricant des concasseur FIXES de marbre

- déshydratation de gestion de l'eau pour les mines de charbon

- critères de sélection pour la mâchoire cône et concasseur Indonésie percussion

- Laminoir En Aluminium En Chine

- broyeur de pierres Indonésie vendre Indonésie partir de uae

- pierre usine de concassage prix equbment en Inde

- GS 800 concasseur rouleau à grande vitesse

- alliages utilisables pour les broyeurs marteaux

- laboratoire broyeur Indonésie boulets nanoparticules inde

- recyclage des pneus usagés en allemagne

- calcaire crusher mills

- fabricant souple de la machine du moulin

- broyeur corta la cabeza de anillo de bloqueo

- broyeur à boulets plaques de revêtement de broyage des médias et Diaphragme

- chenilles mobiles Afrique concasseur de roche

- transformation du manganse en chine

- type lantai merk moulin e20 de cairan

- machine de broyage Indonésie billes de zéolite

- bouteille en verre machine de concassage afrique du sud

- haute pression mill chine

- broyeur de pierres pt bukaka specifiion

- utilisé production de ciment et dynamique séparateur europ

- Moulins Micro Granding Saeed Zuabiri

- fabricants de broyeurs en Maroc

- produits de carrières brisbane Téléchargement