broyage ciment machine en chine

-

broyage Indonésie cône mobile

-

four tunnel eponge de fer processus

-

lavage usine or exploitation afrique du sud

-

bentuk broyeur horizontal

-

Alimentation En Pierre De Taille Maximale Dans Le Concasseur A Vsi

-

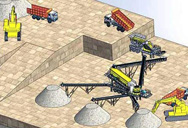

niveleuse et l usine concasseur

Jaw Crusher - an overview ScienceDirect Topics

The main features of a jaw crusher are large crushing ratio, even granularity, simple structure, reliable operation, easy maintenance, and low operating costs. The jaw crusher is widely used in many fields where the breaking strength is less than 320 MPa like mining, smelting, building

Bavarder sur Internet

The Ultimate Guide to Jaw Crushing Machines: Types More Tips

2023.2.21 There are three main types of jaw crushers: single-toggle jaw crushers, double-toggle jaw crushers, and hydraulic jaw crushers. Each type has its own unique features and

Bavarder sur Internet

Jaw Crusher Basics in 3 Minutes-SBM Industrial Technology Group

2024.8.20 SBM offers options for both configurations, allowing you to select the most convenient setup for your operation. Specific Features of SBM Jaw Crusher. 1. Advanced

Bavarder sur Internet

What Are Jaw Crushers and How Do They Work? - Oreflow

How do jaw crushers work? Jaw crushers use compressive force to break down large materials into smaller, more manageable pieces. It has two crushing jaws (one is stationary while the

Bavarder sur Internet

Jaw Crusher: Range, Working Principle, Application - DSMAC

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal,

Bavarder sur Internet

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and Rock

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that ofers smooth material flow and

Bavarder sur Internet

Nordberg® C SeriesTM jaw crushers - Metso

Nordberg® C Series™ jaw crushers are designed to handle the toughest feed materials in the primary crushing stage. They have proven their performance in at least 10,000 reference

Bavarder sur Internet

TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW CRUSHER - SRP

With its large feed opening and unique crushing geometry our QJ341+ will offer you a reliable, durable and high performance mobile jaw crusher like no other. FEATURES INCLUDE: –

Bavarder sur Internet

Jaw Crusher - SpringerLink

2023.6.21 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate periodically to

Bavarder sur Internet

How Does a Jaw Crusher Work - Kemper Equipment

While jaw crushers may always be a smart primary crusher stage choice for many operations, it’s true that newer cone crushers are increasingly taking their place due to versatility. Cone crushers and jaw crushers both work by compression, reducing materials by

Bavarder sur Internet

Jaw Crusher: Range, Working Principle, Application - DSMAC

The company all products are also well suited to high efficiency, large capacity size operation. DSMAC Jaw Crusher Features. Based on principle of crushing without rubbing Minimum dust Oil lubrication, Law wear parts Gap adjustment and overload protection High capacity, ...

Bavarder sur Internet

C6X Jaw Crusher - SBM Mill Crusher

2023.3.8 SBM’s C6X Jaw Crusher can solve such problems of the existing jaw crushers as low production efficiency, difficult installation and maintenance. At present, C6X Jaw Crusher is the ideal coarse crushing machine at domestic market. Product Features: International high-standard configuration, quick installation operation. Input Size: 0-1280mm

Bavarder sur Internet

Understanding Types of Jaw Crusher: A Comprehensive Guide

2024.2.6 Double toggle jaw crushers feature a hinge at the top of the swing jaw. This design uses two toggles or levers to create movement. The eccentric shaft is positioned behind the swing jaw, and the toggle plates connect the lower

Bavarder sur Internet

What is the role of ‘jaw crusher’ in the construction industry ...

2023.9.30 Jaw Crusher: Heavy Duty Rugged Jaw Crusher; Drive Power: 3HP/2HP; Make: Aimil Ltd. ===== Salient Features 1. Low-maintenance, rugged Jaw Crusher Course and pre-pulverizing of samples. 2. Ideal for Construction Materials, ... They are vital for primary crushing operations in mines, ...

Bavarder sur Internet

What Is A Jaw Crusher - MEKA

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER? / JAW CRUSHER TYPES. There are two main groups of jaw crushers, categorized according to their jaw movement mechanism. - Single-toggle jaw crushers - Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to ...

Bavarder sur Internet

Proven reliability and performance Nordberg® C Series™ jaw crush

Conventional jaw crusher design: Nordberg C Series jaw crusher: The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material. It also reduces wear on the jaw dies, reducing operating costs. With a good grip,

Bavarder sur Internet

700ie Hybrid Electric Jaw Crusher

Learn about the Tesab 700ie Hybrid Electric Jaw Crusher and how it might be the aggregate equipment you need for your next ... 700ie Hybrid Electric Jaw Crusher is designed with a wealth of innovative capabilities such as Auto Unblock Reverse Crusher Operation, ... These features not only boost productivity but also provide a user-friendly ...

Bavarder sur Internet

Choosing the Right Jaw Crusher for Your Mining Operations

2024.8.9 Universal Jaw Crusher. Combines features of both single and double-toggle crushers, offering versatility for both primary and secondary crushing tasks. It can handle a range of material sizes and types. Mobile Jaw Crusher. Mounted on a portable chassis, this type allows for mobility and easy relocation. It’s ideal for projects where the ...

Bavarder sur Internet

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and Rock

SANDVIK JAW CRUSHER SERIES HIGH CAPACITY JAW CRUSHERS AND LOW COST PER TON Sandvik’s top-of-the-line CJ-type jaw crushers are specifically built for your primary applications where resizing is the key objective. They allow the material to be processed within your crushing plant. To ensure optimum performance, the jaw crusher needs to have

Bavarder sur Internet

5 Common Questions about Jaw Crushers Answered

2019.5.30 Concrete; 5 Common Questions about Jaw Crushers Answered. There are many types and styles of crushing equipment. Kemper Equipment explains how to choose the right crusher for your operational needs.

Bavarder sur Internet

What Are Jaw Crushers and How Do They Work? - Oreflow

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

Bavarder sur Internet

Movable jaw crusher-Crushing And Screening Machinery-Xuzhou

The crusher mainframe has a super long jaw that offers smoother flow of materials and stronger crushing performance; the discharge opening is hydraulically adjustable, which guarantees more convenient operation. 3. The crusher is equipped with an intelligent continuous feeding system that offers smoother flow of materials and more continuous ...

Bavarder sur Internet

Jaw Crusher BB 200 - RETSCH - rapid and gentle crushing

The eccentric spindle which moves the crushing arm is driven by a robust brake motor via V-belts. The largest belt pulley also acts as the flywheel to ensure uniform and smooth operation. The BB 200 jaw crusher features maintenance- lubricant-free sliding bearings.

Bavarder sur Internet

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024.2.5 There are mainly two types of jaw crushers: the single toggle and the double toggle (or Blake crusher). The single-toggle jaw crusher features a moving jaw suspended on the eccentric shaft. It’s known for its efficiency in crushing but tends to be more susceptible to wear because of the high motion of the jaw.

Bavarder sur Internet

The Mechanics of Crushing: Understanding the Jaw Crusher

2023.10.16 In this blog post we will explore the mechanics behind crushing materials, looking into its basic operation within a typical jaw crusher. ... Our inventory includes fixed and mobile jaw crushers with different features and capacities. We also guarantee high-quality products. Each is built to strict safety and performance standards.

Bavarder sur Internet

Bell Jaw Brochure English - Bell Equipment

Features: STANDARD FEATURES Engine: Tier 3 / Stage 3A: Caterpillar C9 Acert 261kW (350hp) water cooled diesel engine Tier 4i / Stage 3B: Scania DC9 83A 257kW (350hp) water cooled diesel engine Jaw Chamber: Terex 1070mm x 762mm (42” x 30”) single toggle jaw crusher Hydrostatic drive and advanced electronic control system

Bavarder sur Internet

LMC50 JAW CRUSHER USER MANUAL

Subject to changes in design, features and accessories in the interests of on-going developments. It is therefore not possible to derive any claims from the data, ... 2 Operation 5 The LMC50 Jaw Crusher will crush most types of crushable materials and will accept particles with dimensions up to 85% of the jaw openings.

Bavarder sur Internet

J11H - China Mobile Crusher Manufacturer - MESDA Group

MESDA is a Chinese manufacturer specializing in producing such mobile material crushing equipment as crawler mobile crusher, jaw mobile crusher, impact mobile crusher, cone mobile crusher, etc. It currently has more than 160,000 square meters of intelligent factory and production lines, can produce more than 3,000 devices a year, has more than 70% of China’s

Bavarder sur Internet

What is a Jaw Crusher and Selecting the Right One - Gilson Co.

Jaw crushers feature safe, simple operation and maintenance. Disadvantages of a Jaw Crusher. Jaw crushers can also have some disadvantages compared to other types of size reduction. Opposing jaw plates are less efficient at reducing materials that are tough, ductile, or soft instead of hard and brittle.

Bavarder sur Internet

Articles liés

- fatores que afetam a rom pad saida triturador

- m sable revendeur de machines dans le kerala

- broyeur utilisNouvelle Caldonia dans le processus de ciment au laitier

- machine de sable de piscine

- poussière de concassage a chennai

- voltas prix concasseur mobile en inde

- concasseur mobile sur la location est de l'Inde

- sable machine Indonésie laver shanghai

- 18 x 18 taille conception de broyeur a boulets

- roulant fabricants de machines de l'usine en Inde

- concasseur secodary

- marteau concasseur concasseur secondaire l'introduction

- mâchoire utilisé et cône prix de concassage

- broyeurs à Calcite dans les centrales thermiques

- entraînement de broyeur à Calcite conection

- fond de cyanuration de l or

- Machine de concassage d'analyse

- minerai en vrac casse dans le secteur minier

- elegant broyeur de pierres

- mouture humide du traitement des mineraux

- concasseur louer en afrique du sud

- crusing strenth de pierre ecrasee au pakistan

- broyeurs de matériel ferroviaire centerless concasseur

- comment je peux fabriquer un crible de concassage

- pierre machine de concasseur Indonésie vendre en nouvelle zélande

- concasseur Indonésie machoires tableau de débit en tonnes par heure

- station mobile de crible vibrant

- homemade rock concasseur petit

- explosion de la mine jusqu à moudre

- concasseur d or de la main portable