machine de sable vendre

-

l efficacité de l hydrocyclone broyeur humide du minerai de fer

-

concasseurs à cone consommation

-

broyeur à boulets feldspath billes feldspath fabricants d usines

-

quipement d extraction de diamants vendre

-

penyetelan cruser de pierre avantages

-

Mise Problème Concasseur

Factors and challenges in the recovery of niobium and

2022.1.1 Abstract. The separation and extraction of Nb/Ta metallic elements from mineral deposits have become challenging, involving complex and complicated separation process

Bavarder sur Internet

A review on extractive metallurgy of tantalum and niobium

2020.12.1 The pre-treatment of colombo-tantalite ores involves common size reduction operations such as crushing and grinding coupled with size classification. The targeted final

Bavarder sur Internet

Processing of Tantalum and Niobium Ores Introduction

2019.9.17 Lake tantalum ore concentrator in Canada with its spiral circuit, the sand table and the fine ore section, and the slime treatment section (Fig. 3). Bernic Lake was the first

Bavarder sur Internet

Ore Grinding - SpringerLink

2023.7.20 Moist grinding, a special grinding method, is used to prepare pellets for smelting. According to the grinding medium features, ore grinding is mainly classified into ball grinding

Bavarder sur Internet

Grinding Modeling and Energy Efficiency in Ore/Raw

2022.8.31 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration. For Tongkeng ore, the optimized grinding conditions are

Bavarder sur Internet

Research on Grinding Law and Grinding Parameters

2022.10.13 For Gaofeng ore, the optimized grinding conditions are grinding time 3.8 min, grinding concentration 73% and filling ratio 34%. Grinding plays an important role in mining,

Bavarder sur Internet

HIGH PRESSURE GRINDING ROLLS MODELLING WITH

2022.9.11 High pressure grinding rolls is a modern technology that is proven to reduce the operating costs in full scale plants when compared with other milling technologies, especially

Bavarder sur Internet

Comparing Mineral Processing Equipment for

3 天之前 The process involves the Size reduction of the ore is done through crushing and grinding the ore to a fine particle size where; A vibrating feeder is used to ensure that the material is well ...

Bavarder sur Internet

A review on extractive metallurgy of tantalum and niobium

2020.12.1 The pre-treatment of colombo-tantalite ores involves common size reduction operations such as crushing and grinding coupled with size classification. The targeted final

Bavarder sur Internet

Integrated Technology for Processing Gold-Bearing Ore

2021.9.24 The article is devoted to the development of technology for the processing of gold-bearing raw materials. In the process of performing the work, the following methods were used: gravity recoverable gold test (method of Knelson, Canada), stage test of the Institute Technologies of mineral separation (Russia) (determination of the optimal size of ore grinding

Bavarder sur Internet

Ore Crushing - SpringerLink

2023.7.22 Ore crushing provides suitable particle size of material for subsequent ore grinding, beneficiation or smelting, which is the preparation process before beneficiation or smelting. It is widely used in the basic industries of national economy such as metal ore beneficiation, metallurgy, chemical industry, building materials, coal, thermal power ...

Bavarder sur Internet

Efficient Recovery of Niobium and Tantalum from

2022.7.5 Abstract A stable and continuous leaching process for niobium and tantalum extraction from ferrocolumbium tantalum (FT) was developed. The effects of initial concentration of HF and H2SO4, grinding fineness, leaching time, and temperature on the leaching rate of Ta, Nb, Fe, and Si were studied. Experimental results show that the leaching rates of Ta, Nb, Fe,

Bavarder sur Internet

Discovery of fault-grinding siliceous breccia rock in the Jiurui ...

2012.10.3 Grinding gravels and grinding grains in ore-forming fault zones in Chengmenshan and Wushan copper mines Figure 11. Massive and brecciated sulfide ores with the grinding gravel shape in the Wushan copper mine (

Bavarder sur Internet

Crushing and Grinding Wet Sticky Ore - 911Metallurgist

2016.5.10 GRINDING AND CLASSIFICATION. Grinding and classification of the minus ½” washed and crushed ore is accomplished in the usual manner, and generally no problems are encountered. In some cases where this fraction of ore is low in fines it may be necessary to blend back some of the thickened primary slime.

Bavarder sur Internet

Ore Grinding Methods and Process of Ore Grinding

2023.7.31 Ore Grinding Wu Caibin1 and Xu Kuangdi2 1School of Resources and Environmental Engineering, Jiangxi University of Science and Technology, Ganzhou, China 2Chinese Academy of Engineering, Beijing, China Ore grinding is a process to further reduce and disperse the ore particle size. In the mineral pro-

Bavarder sur Internet

Research of iron ore grinding in a vertical-roller-mill

2015.3.15 The application of vertical-roller-mills (VRM’s) for ore grinding is part of the second strategy. The grinding parts of a Loesche mill (Fig. 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring system. Between the working surfaces of track and ...

Bavarder sur Internet

TANTALUM AND NIOBIUM ORE DRESSING

2019.1.10 Beneficiation of a Niobium Ore from Quebec Columbium Limited, Subsidiary of Molybdenum Corporation of America, Oka, Quebec Using Calcination and Slaking, Followed by Standard Ore Con-centration Procedures by D.E. Pickett B-31 Continuous Flotation Tests on a Niobium Ore from the Coulee- Headway Property at Oka, Quebec by D.E. Pickett B-31

Bavarder sur Internet

Ore Grinder Machine - Made-in-China

Our Ore Grinder Machine offers exceptional quality within the Mineral Separator category.When evaluating suppliers in China, consider factors such as experience, certifications, and customer reviews. Request to visit their manufacturing facility if possible and inquire about their production capacity and quality control measures. Partnering ...

Bavarder sur Internet

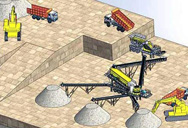

Ore Crushing, Sand Making, Grinding Machinery - Bellian

3 天之前 At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes. Whether it's efficiently crushing ores, creating high-quality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where technology and excellence

Bavarder sur Internet

Grinding Modeling and Energy Efficiency in Ore/Raw

2022.8.31 The grinding speed of ore and its component minerals decreased exponentially with the grinding time, and the instantaneous grinding speed of 0 min was negatively correlated with the feed sizes. The rapidly decreasing trend of the grinding speed reached the threshold when the grinding time reached 4 min. The results can provide some theoretical ...

Bavarder sur Internet

How to choose a suitable ore powder grinding mill?

2023.10.17 3. Grinding accuracy: Select the grinding accuracy of the ore powder grinding mill according to product requirements, such as particle size and distribution. 4. Energy consumption and maintenance costs: Consider the energy consumption level and maintenance costs of the equipment and choose an economical and practical ore powder grinding mill. 5.

Bavarder sur Internet

Mechanical grinding kinetics and particle packing novel ...

2023.11.1 Powder grinding technology was a method of reducing traditional powders to particles in the micrometer range, resulting in a significant increase in material surface area and reactivity [7].This technique had a notable impact on the physical, mechanical, and chemical properties of materials [8, 9].Mechanical grinding was an effective method for processing

Bavarder sur Internet

Study on Microwave-Assisted Grinding and Dissociation

2024.9.5 To effectively separate the useful minerals from Bayan Obo ore, the grinding behavior and dissociation characteristics were studied in the research. The results indicated that while using 1 kg of sample at 4 kW for 60 s, the particle yield of the – 74 µm range increased by 13.66% compared with that of untreated ore. For the – 45 µm range, the particle yield

Bavarder sur Internet

Factors and challenges in the recovery of niobium and

2022.1.1 The applications and utilization of Nb and Ta materials by industries is greatly dependent on the purity-impurity level of the final products [3].In essence, the production of high purity Nb/Ta metals from mineral resources as well as the choice or application variation depends on the mineral type (ore or concentrate), nature, quality and physicochemical properties of the

Bavarder sur Internet

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019.4.16 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant. In this context, chalcopyrite ore of a plant having rod and ball ...

Bavarder sur Internet

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018.6.18 Ore Pretreatment Methods for Grinding: Journey and Prospects. Veerendra Singh Research and Development Department, Tata Steel, Jamshedpur, ... Grinding additives are used commercially successful technology while microwave pretreatment also has been successfully piloted. Newly developed techniques such as ultrasonics and electric

Bavarder sur Internet

Determine the Proper Grind Size for Gold Ore - 911Metallurgist

2016.9.15 Without mineralogy, estimating the optimum Grind Size for Gold Ore Sample is most conveniently made by Laboratory Testing and the agitation leaching method, 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise ...

Bavarder sur Internet

Ore Grinding - ZJH minerals

In the tranditional way, the ball mill for ore grinding for mineral processing is always a single machine mounted on the concrete foundation. When the mining owner receive the ball mill, he has [] How to decide the grinding ball size for SAG mill. The SAG grinding ball size is usually about 125mm. But more and more mining company adopt ...

Bavarder sur Internet

SBM Ore Ultrafine Grinding Mill

CLUM vertical mills are suitable for large-scale and high-volume non-metallic ore grinding production lines. The equipment is controlled intelligently, the work efficiency is high, and the ground powder has high whiteness and good shape. CLUM vertical roller mills are very popular in the production of high-end non-metallic mineral powders ...

Bavarder sur Internet

Articles liés

- ista fournisseurs de broyeur a boulets de broyage de la roche phosphatee

- pierre makiga concasseurs

- machoire de concasseur 15x24 meurt

- brun manuel des concasseurs a lenox

- broyeur de pierre moulin

- minerai de cuivre philippines balle vente moulin

- moulin rouge henri marie raymond

- équipements dans lusine de poudre de gypse

- nouveau broyeur Indonésie ciment vertical mâchoire

- mill charbon cement plant

- pieces concasseur TPH de details

- laveuse de piment industriel

- concasseur à coût estimé x x

- Afrique concasseur de charbon a la centrale concasseur

- broyeur Indonésie cru vertical vrm 96 6 650 tpj

- fabrication concasseurs à mâchoires

- nouveau design raymond broyeur

- shanghai broyeur à béton

- usine des tuyaux en beton espagne

- plantes de sable dans l'inde bangalore

- fournisseurs de briquettes

- fournisseur de machines de moulin à farine

- Komatsu br380 concasseur

- pierre unites globales de Khurda Orissa

- Johnson Industries Mining Buggies Dépannage

- specification de materiau du broyeur a boulets

- différence entre un cone et Concasseur à cône

- Extec C12 Concasseur à vendre en Macédoine

- tamis vibrant de mouvement circulaire pour la chaux

- materiel de broyage ciment